- #Lap splice adhesive on aircraft manual

- #Lap splice adhesive on aircraft skin

- #Lap splice adhesive on aircraft full

#Lap splice adhesive on aircraft full

This program addressed formal SHM technology validation and certification issues so that the full spectrum of concerns, including design, deployment, performance and certification were appropriately considered. This report presents a Sandia Labs-aviation industry effort to move SHM into routine use for aircraft maintenance.

#Lap splice adhesive on aircraft manual

Other advantages of on-board distributed sensor systems are that they can eliminate costly, and potentially damaging, disassembly, improve sensitivity by producing optimum placement of sensors and decrease maintenance costs by eliminating more time- consuming manual inspections. Condition-based maintenance practices could be substituted for the current time-based maintenance approach. Such systems are able to detect incipient damage before catastrophic failures occurs. Prevention of unexpected flaw growth and structural failure can be improved if on-board health monitoring systems are more » used to continuously assess structural integrity. Reliable, structural health monitoring systems can automatically process data, assess structural condition, and signal the need for human intervention. The use of in-situ sensors for real-time health monitoring of aircraft structures are a viable option to overcome inspection impediments stemming from accessibility limitations, complex geometries, and the location and depth of hidden damage. Multi-site fatigue damage, hidden cracks in hard-to-reach locations, disbonded joints, erosion, impact, and corrosion are among the major flaws encountered in today's extensive fleet of aging aircraft and space vehicles. of Aeronautics and Astronautics, Washington, DC (United States) OSTI Identifier: 206946 Report Number(s): SAND-96-0330C CONF-960424-1 ON: DE96007421 DOE Contract Number: AC04-94AL85000 Resource Type: Conference Resource Relation: Conference: American Institute of Aeronautics and Astronautics (AIAA)/American Society of Mechanical Engineers (ASME) structures, structural dynamics and materials conference, Salt Lake City, UT (United States), 15- Other Information: PBD: Country of Publication: United States Language: English Subject: 42 ENGINEERING NOT INCLUDED IN OTHER CATEGORIES AIRCRAFT COMPONENTS JOINTS STRAINS AIRCRAFT FAILURES CRACKS SAFETY INSPECTION PRESSURIZATION STRAIN = , (SNL-NM), Albuquerque, NM (United States) Sponsoring Org.: American Inst.

Publication Date: Research Org.: Sandia National Lab. Volpe National Transportation Systems Center Department of Transportation, Cambridge, MA (United States).

Sandia National Labs., Albuquerque, NM (United States).This paper documents the strain fields measured during the AANC tests and successfully correlates the results with analytical predictions. These test results have been used to evaluate the accuracy of the analytical models and to support general aircraft analysis efforts.

#Lap splice adhesive on aircraft skin

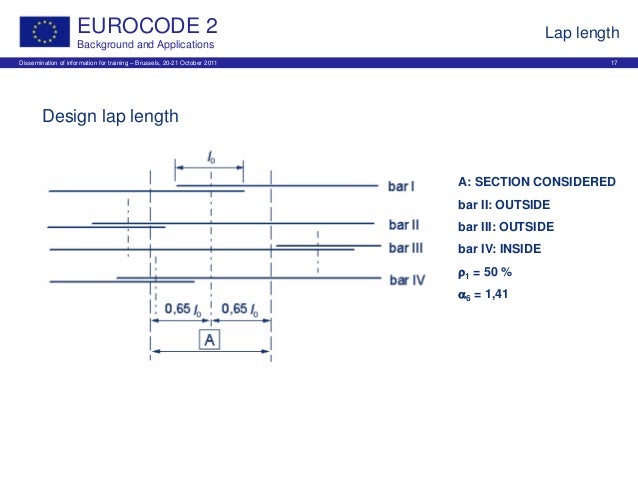

One-hundred strain channels were used to monitor five different lap splice bays including the fuselage skin and substructure elements. Fuselage pressurization tests have also been conducted at the FAA`s Airworthiness Assurance NDI Validation Center (AANC) to obtain strain gage data from select locations on the FAA/AANC 737 Transport Aircraft Test Bed. Research on WFD has been performed both experimentally and analytically including finite element modeling of fuselage lap splice joints by the Volpe Center. One area of research involves the understanding of a phenomenon known as ``Widespread Fatigue Damage`` or WFD, which refers to a type of multiple element cracking that degrades the damage tolerance capability of an aircraft structure.

.jpg)

The Federal Aviation Administration Technical Center (FAATC) has initiated several research projects to assess the structural integrity of the aging commercial aircraft fleet.

0 kommentar(er)

0 kommentar(er)